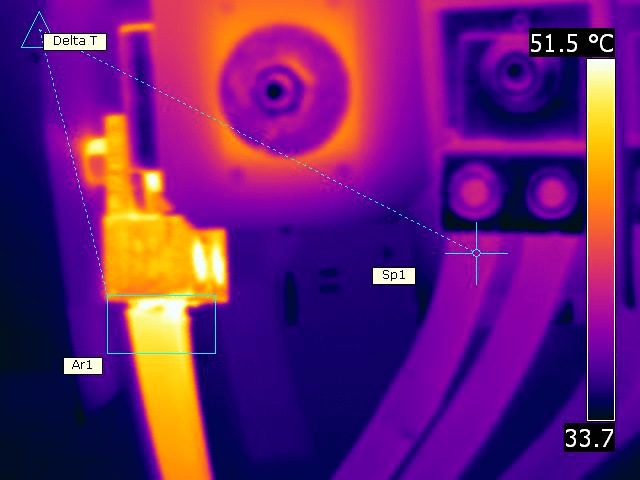

Abnormal temperatures and infrared emissions are the key to revealing electrical component failures. The early detection of these failures by non-contact temperature measurement and analysis allows for repairs, often before the failures are visually apparent, and usually at a significant savings over unexpected emergency repairs.

Regularly scheduled thermographic surveys typically include an inventory of all the equipment included and a separate listing for each trouble area found. Each subsequent survey allows for a comparison of the condition of the electrical equipment and the confirmation of previous repairs.

Any areas that indicate abnormal temperatures would be recorded including both thermal and visible light images, temperature comparisons to similar components, present current draw as well as current capacity, time of day and location and the criticality of the component. In addition, any electrical connections that can be tightened at the time of the survey, may provide an immediate repair and often account for a significant percentage of problems found.

If you are interested in finding out more about Infrared Thermography or scheduling a survey, contact us at 717.392.0804. Our group of highly training electricians look forward to the opportunity to meet with you and discuss how Lapp Electric can help you.